General information about electric chain hoists

Apart from the usual criterion such as lifting capacity, lifting speed and dimensions also consider following:

1. Choosing a motor according to FEM 9.682

In addition to the torque the decisive criterion for rating an electric motor is the heat it generates. Here we differentiate between two operational modes.

1.1 Intermittent duty

In this case the motor is designed for a series of equal cycles consisting of duty periods with constant load and rest periods. The heat generation depends on the relative duty cycle, that is, the relationship between operating period under load, total operating time and the number of starts/hour.

Duty rating ED = (Operating period / Operating period + rest periods) %

The number of cycles that can be made under full load is calculated as follows:

S ≈ 0,3 x ED x V / H

· S = Cycles per hour

· ED = Duty rating in %

· V = Lifting speed in m/min.

· H = Average lifting height in m

A cycle consists of a motion of lifting, lowering and the rest periods. One must ensure that the lifting height does not exceed the value permitted by the percentage duty cycle referred to a cycle period of 10 minutes.

H ≤ ED x V / 20

and that simultaneously the permissible number of starts is not exceeded. It is generally accepted that a cycle consists of 6 starts.

1.2 Short time duty

Where special duty conditions exist (e.g. long hook path) the operating period must be of such length that the admissible temperature limit of the motor is not exceeded. For such cases intermittent duty must be replaced by short time duty. That is, the motor may be operated for up to 10 starts over a certain period (usually 15 min.). Thereafter the motor must cool down to room temperature.

2. Classification of hoisting equipment according to FEM 9.511

To choose an optimal hoist the lifting capacity and also the classification group must be known. The classification group indicates the theoretical operating time of the mechanical components under full load:

Classification group | 1Bm | 1Am | 2m |

Operating time in h | 400 | 800 | 1600 |

If the hoist is operated as classified an actual operating time of around 10 years can be expected. After this period a general overhaul is necessary. To define the classification group following values must be determined:

2.1 Average operating time per day

The average operating time can be estimated or calculated as follows:

Operating time/day = (2 x average hook path x cycles /hour x operating time/day / 60 x lifting speed

Electric hoists provided with counters for operating hours and number of starts simplifiy the classification

2.2 Load spectrum

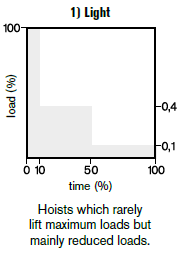

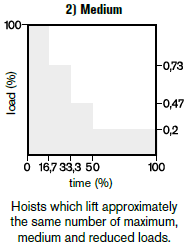

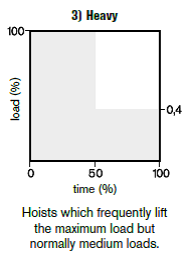

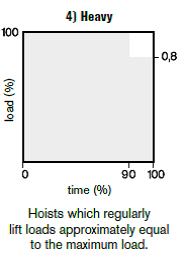

The load spectrum indicates to what extent a hoist or part thereof is subject to maximal stress or whether it is subject to smaller loads only. It can be calculated or estimated according to the diagrams on the right:

2.3 Classification

The classification group is defined by operating hours and load spectrum: